STRABAG AG

“Etschel Brunnenservice is the right partner for guaranteeing quality in our well construction and service.”

With our HPI-Process we perform the world´s leading development and rehabilitation process for water wells. Developing this outstanding method in 1993, we have more than 30 years of experience with this technology. Due to the effectiveness of HPI-Process a water well can be fully rehabilitated within hours.

With over 13.000 wells rehabilitated we could develop the process further and perfectioned it during the decades. Our goal is to bring every well to it´s best possible condition and have happy customers every day. Best quality is what Etschel Brunnenservice stands for.

Climate change is having a significant impact on the water supply industry. Groundwater levels are lowering, wells are more vulnerable to aging, and water is a finite resource. This poses enormous challenges for the entire industry. Our work begins at the start of a long journey that water must travel to get from underground to the pipes of homes and industry.

By ensuring that wells can continue to operate at their maximum capacity, we lay an important foundation for maintaining water availability and ensuring that we can continue to enjoy the best quality water. With this specifically imposed commitment, we have also defined our vision:

“With our technologies we want to contribute that countries all over the world have the possibility to benefit from water in its best quality possible.”

Every well is subject to aging over a period of time. Like any living thing, also a well has a limited life span. During the entire operating time of the well, the aforementioned aging phenomena ensure that the performance and pumping capability decline.

The “medicine” that increases the life of the well is rehabilitation. By removing unwanted solids, the performance of the well is increased again.

The more often the well undergoes rehabilitation, the longer it can ultimately operate. The useful rehabilitation cycles vary from well to well, but can be determined relatively accurately by regular checks.

Innovative Techniques and Technologies for Well Regeneration:

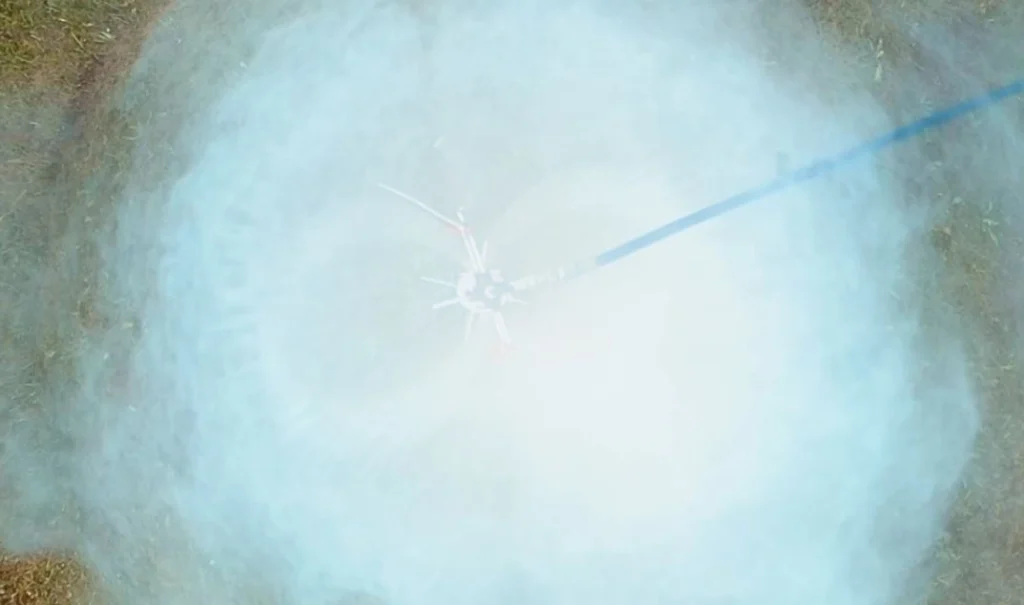

The most innovative and effective method for well rehabilitation is the HPI process performed with the JET Master. This process meets all the important criteria for successful borehole cleaning. It is used for both pre-cleaning and rehabilitation and treats a large area due to its 2 nozzle levels. This makes this process much faster than others. Furthermore, it has an enormous depth of action and dissolves soft and hard deposits up to 6.5ft. behind the filter media. It can be used on all filter media and will not damage the material. During the process, the dirty water is pumped directly from the well and measurements can be made outside. This makes the HPI-Process the all-in-one solution for cleaning wells and usually requires only a few hours to complete cleaning.

The HPI Process powered by the JET Master is only available from Etschel Brunnenservice. We are convinced that with our process the maximum possible pumping capacity is extracted from every well. This not only extends the lifetime and the rehabilitation cycles of the well. In times of strongly increased electricity and energy prices, it is also a very important factor that the well can be operated in a sustainable, cost-saving and energy-efficient way. This is because the higher the performance of the well, the less energy has to be used to pump a desired flow rate. Consequently, in terms of economy, it is advisable to have wells cleaned with the HPI Process.

With our decades of experience and over 13,000 rehabilitated wells, we have already experienced numerous highlights. For example, we have already been in action at a well that serves the sprinkler system of a BMW test track. Another application was in a large nuclear power plant in Switzerland, where enormous safety precautions had to be taken.

In another project, we had to fly our equipment up the mountain by helicopter because the wells there could not be reached by vehicles. In addition to our operations at the well, however, visits to our partners are also a major highlight. Whether in Indonesia, Poland or the USA. All over the world, we met great people and companies with fantastic stories who were interested in our technology. Today, we are all the more proud that the HPI Process is now being used successfully on 3 continents.

Do you rehabilitate and develop wells yourself but the methods you use do not produce the desired results and take too much time?

Then come to us and secure our know-how and technology to become the market leader in your country or state. We will provide you with an offer that exactly fits your needs and help you to integrate the HPI-Process in your company.

Of course, we can also train your staff so that you can make ideal use of the new process. Invest in the future of your business and secure the world’s best technology for well development and rehabilitation for your area on an exclusive or non-exclusive basis.

The most common causes of well aging are clogging, silting, sintering or corrosion. All of these aging phenomena cause the well's production capacity to decrease. In most cases, the phenomena occur in the form of deposits that settle on the filter material and the filter slots, in the gravel pack or in the surrounding rock. There they increasingly block the waterways and inhibit the flow.

The diagnosis that a well needs to be rehabilitated is usually made by a TV inspection. For this purpose, we have high-tech cameras with radial and axial view, with which we can see into the wells and precisely view every point of it. With integrated laser technology and 10x zoom, we can measure damaged areas and take detailed, high-resolution pictures. On the images of the TV scan, the deposits or corrosion phenomena in the well can be made visible and a rehabilitation concept can be developed.

We have a wide range of well rehabilitation methods that we can use for cleaning wells. These include, for example, brushing, swabbing, intensive extraction, high-pressure internal rinsing, the pressure pulse method with compressed gases or chemical methods. In over 95% we use our High Pressure Impulse Process powered by the JET Master, as this is the most effective and most promising method.

It depends on numerous factors. Some wells need to be rehabilitated once a year. Other wells are still in a good condition after decades. Regular TV-inspections help to find out the right intervals for rehabilitation. If your well is losing capacity, pumping sand or behaves unusual, it is the right time to have a look inside the well.

It depends on the method. Some well rehabilitation services take several days. The fastest method is the HPI-Process powered by the JET Master. It takes only 3 to 4 hours to fully rehabilitate a 100m deep well.

We are in the well maintance sector for more than 100 years and have a team of experts, hydro geologists, engineers and very experienced staff. Our main goal is to have satisfied customers at the end of the day. Therefore, our strategy is to always offer the best service, provide authentic advice to our customers and find high quality solutions. To achieve this, we work in a sustainable, environmentally friendly and service-oriented manner.